42 steel process description

The Steel Manufacturing Process - How is Steel Made? The modern-day steel production process began in 1856 under a process known as the Bessemer process. It's largely considered to be the first process used to mass-produce steel. Bessemer process - Wikipedia High-quality steel was made by the reverse process of adding carbon to carbon-free wrought iron, usually imported from Sweden. The manufacturing process, called the cementation process, consisted of heating bars of wrought iron together with charcoal for periods of up to a week in a long stone box. This produced blister steel.

Iron & Steel Industry | Process Description ... The role of iron and steel industry in India is very important for the development of the country. This video clearly explains the detailed Process involved ...

Steel process description

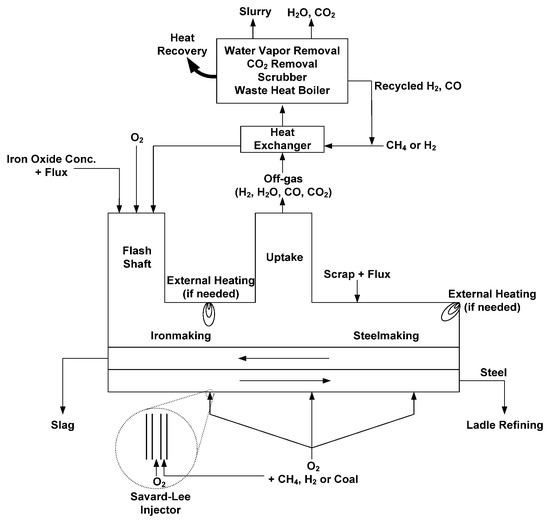

Steelmaking Process - an overview | ScienceDirect Topics Steelmaking Process During the steelmaking process, fluxes that consist of lime (CaO) or dolomitic lime, with iron and scraps, are charged to the furnace. From: The Utilization of Slag in Civil Infrastructure Construction, 2016 Download as PDF About this page P2 and Best Management Practices in Different Industries The Modern Steel Manufacturing Process - ThoughtCo Two processes, basic oxygen steelmaking (BOS) and electric arc furnaces (EAF), account for virtually all steel production. 3 Ironmaking, the first step in making steel, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace. Done For process descriptions.docx - How Steel Is Made ... These two ways can vary or be combined for the production of steel but, for this process description, we will be focusing on making steel with the blast furnace basic oxygen furnace. Ingredients used in steel and what they are: Iron: A lustrous (shining) and ductile metal.

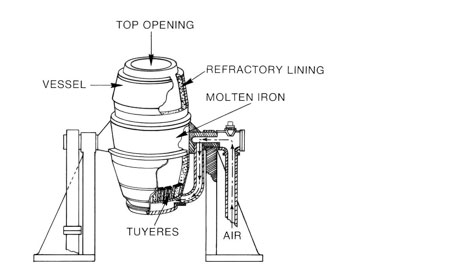

Steel process description. Steelmaking - Wikipedia Modern steelmaking processes can be divided into three steps: primary, secondary and tertiary. Primary steelmaking involves smelting iron into steel. Secondary steelmaking involves adding or removing other elements such as alloying agents and dissolved gases. Tertiary steelmaking involves casting into sheets, rolls or other forms. Bessemer process | Dates, Definition, & Facts | Britannica Air is blown in through openings (tuyeres) near the bottom, creating oxides of silicon and manganese, which become part of the slag, and of carbon, which are carried out in the stream of air. Within a few minutes an ingot of steel can be produced, ready for the forge or rolling mill. steel | Composition, Properties, Types, Grades, & Facts ... steel, alloy of iron and carbon in which the carbon content ranges up to 2 percent (with a higher carbon content, the material is defined as cast iron). By far the most widely used material for building the world's infrastructure and industries, it is used to fabricate everything from sewing needles to oil tankers. PDF Iron and Steel Manufacturing Industry Description and Practices Steel is manufactured by the chemical reduction of iron ore, using an integrated steel manufac-turing process or a direct reduction process. In the conventional integrated steel manufacturing process, the iron from the blast furnace is con-verted to steel in a basic oxygen furnace (BOF). Steel can also be made ...

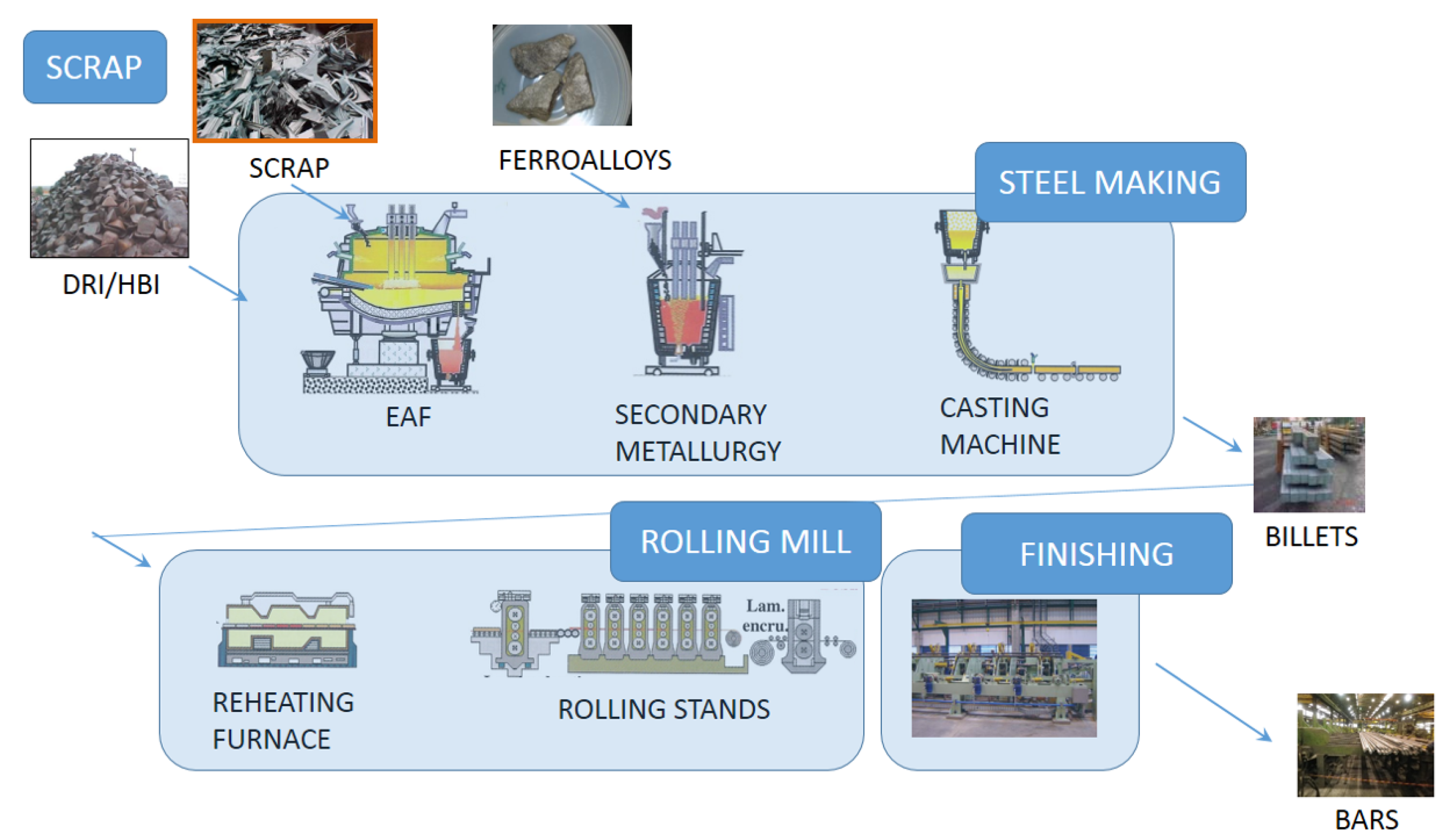

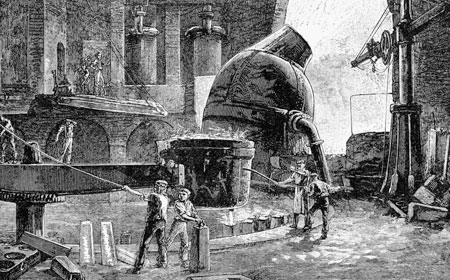

An Overview of Steelmaking Process ... - Steel Technology Steelmaking process involves the production of steel from iron ore and scrap. In this process, various impurities such as silicon, sulfur, nitrogen, phosphorus, and excess carbon are removed from the sourced iron. And, to produce different grades of steel, alloying elements such as nickel, manganese, chromium, and vanadium are added. Steel - Wikipedia Steel is an alloy made up of iron with typically a few tenths of a percent of carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion - and oxidation-resistant need typically an additional 11% chromium. PDF 12.5 Iron And Steel Production The production of steel in an EAF is a batch process. Cycles, or "heats", range from about 1-1/2 to 5 hours to produce carbon steel and from 5 to 10 hours or more to produce alloy steel. Scrap steel is charged to begin a cycle, and alloying agents and slag materials are added for refining. Stages Infographic: the Iron and Steel Manufacturing Process Steel is made primarily in a two-step process. In the primary steelmaking step, liquid iron is converted into steel by the basic oxygen furnace (BOF) process, or by melting scrap steel or direct reduced iron (DRI) in an electric arc furnace. Secondary steelmaking is a refining process in which alloying metals are added and impurities are removed.

Steel making process - ArcelorMittal Steel is produced from iron ore or scrap. Iron ore is a mineral aggregate that can be converted economically into iron. The quality of the iron ore is mainly determined by its composition; a high iron content and low sulphur and phosphorus contents are favorable. Iron ore can be found all over the world, but its iron EOF Steel Production - American Iron and Steel Institute How Steel Is Made Steel is primarily produced using one of two methods: Blast Furnace or Electric Arc Furnace. The blast furnace is the first step in producing steel from iron oxides. The first blast furnaces appeared in the 14th century and produced one ton per day. The Steel Story - worldsteel.org The Bessemer process was the first inexpensive industrial process for the mass-production of steel from molten pig iron. Independently discovered in 1851 by William Kelly, the process had also been used outside of Europe for hundreds of years, but not on an industrial scale.

Steel Manufacturing Process - AIST The molten steel is formulated to precise chemical compositions during the secondary refining processes. The refined steel is then cast into a variety of solid shapes usually by a continuous casting method. The solidified shapes are processed into finished goods by various processes, including hot rolling, cold rolling, annealing and coating.

The Bessemer Steel Process - ThoughtCo The Bessemer Steel Process was a method of producing high-quality steel by shooting air into molten steel to burn off carbon and other impurities. It was named after the British inventor Sir Henry Bessemer, who worked to develop the process in the 1850s.

Done For process descriptions.docx - How Steel Is Made ... These two ways can vary or be combined for the production of steel but, for this process description, we will be focusing on making steel with the blast furnace basic oxygen furnace. Ingredients used in steel and what they are: Iron: A lustrous (shining) and ductile metal.

The Modern Steel Manufacturing Process - ThoughtCo Two processes, basic oxygen steelmaking (BOS) and electric arc furnaces (EAF), account for virtually all steel production. 3 Ironmaking, the first step in making steel, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace.

Steelmaking Process - an overview | ScienceDirect Topics Steelmaking Process During the steelmaking process, fluxes that consist of lime (CaO) or dolomitic lime, with iron and scraps, are charged to the furnace. From: The Utilization of Slag in Civil Infrastructure Construction, 2016 Download as PDF About this page P2 and Best Management Practices in Different Industries

:max_bytes(150000):strip_icc()/464506217-57a5dee43df78cf459cd1ba7.jpg)

0 Response to "42 steel process description"

Post a Comment